From Recycled Waste to World-Class Drums.

The Origin Story

ReThink DRUMS & Percussion started with a question:

What if drums could sound incredible – and be 3D-printed from industrial leftovers?

That question sparked a journey into materials, sound, and sustainability – all rooted in Swedish innovation.

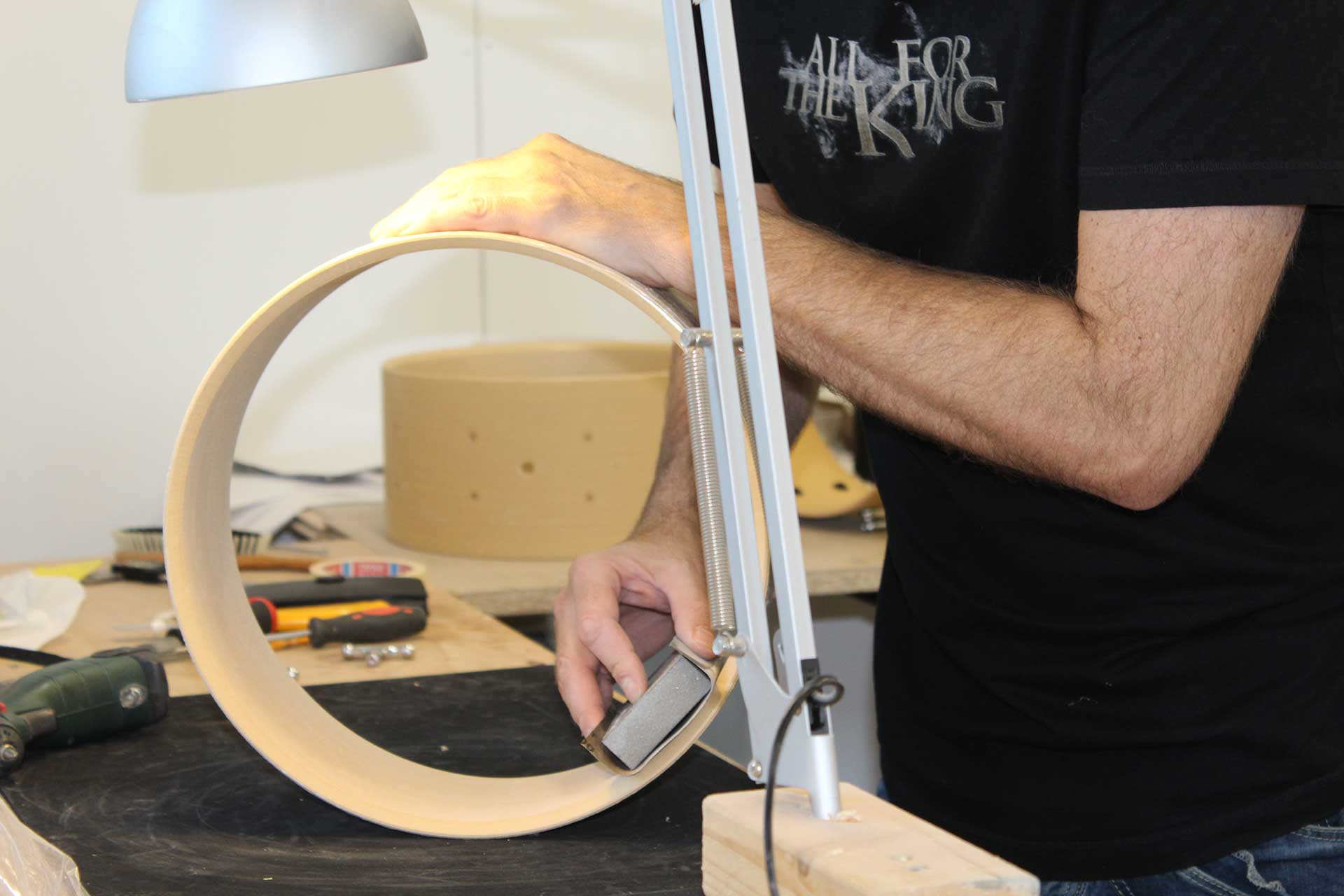

Born out of a small local workshop and a passion for circular thinking, ReThink DRUMS & Percussion became the first drum company in the world to take 3D-printed drums from concept and prototype to full-scale industrial production using recycled materials.

We combine circular design, additive manufacturing, and musical craftsmanship into a new kind of instrument.

No mass production. No greenwashing. Just pure innovation and craftsmanship.

Pro-level drums that don’t just sound great. They make sense.

The Material & The Method

The result? A hybrid construction that delivers:

• Punch and projection of traditional shells

• Warmth and nuance of fine-tuned wood

• Consistency and stability of advanced composites

• A significantly reduced carbon footprint

Every kit is built to order. Every detail is crafted for the player. Every beat makes a difference.